EXTRUDER GEARBOX REPAIR SERVICES

EXTRUDER GEARBOX REPAIR SERVICES

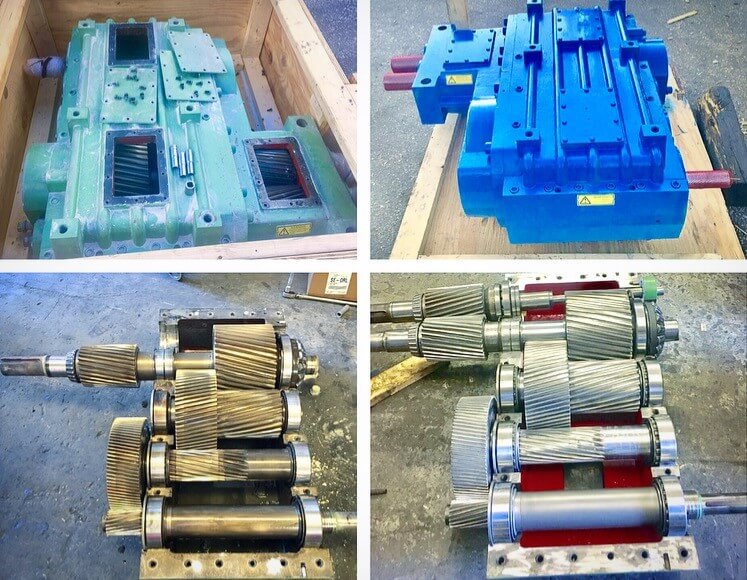

Extruder Gearbox Repair by PPG Works

We’ve been industrial extruder gearbox repair experts with a combined extruder gearboxes experience of over 30 years. We rebuild and recondition extruder gearboxes too! PPG-Works is your one-stop choice for gear repairs. We can restore your gear to OEM specs for only a fraction of the cost of a new gearbox.

Our specialist makes sure that our repairs are done right for the first time, we’ve only had a 9 of 100 returns-for-redos. We’ve got answers to questions as well as solutions to daunting challenges.

A case study of the steel industry machine repair did by us:

An old client of ours brought in a friend who’s having a little problem with the steel fabrication machine. The job required us to rebuild and repair the drive gear case that moves slabs of steel. To restore, we applied MIG welding for renewing the cracks, after which we used CNC machining to re-do the bores to be able to print specifications.

We reamed the holes and assembled the gear case with new hardware, installed the bearing seals, installed idler wheels, we installed and aligned seal rings, and finally, we sandblasted this 8.7” high x 9” long x 4” full gear case before we applied a yellow coating. We ensured we ran a test before delivering it to the client’s facility, and he was well pleased.

Call us today at 713-862-6200 for Free Quote or Contact Us Here!

About PPG:

As part of our platform for industrial wear equipment repair services, Precision Pump & Gear Works reconditions and repairs all types of Gears and Gearboxes. Our shop is equipped with the newest technology machine tools and staffed by knowledgeable technicians with insight based on years of experience in Gear repair. With our five locations in the United States and services that set the industry standard, companies from all over the country leverage our reconditioning and repair capabilities to cost-effectively revitalize their Gearboxes and keep their machinery operating at peak performance.

When Gears are chipped, gouged, damaged, and worn, we bolster their performance by restoring them to OEM specifications. We examine the Gear to determine the cause of failure, such as misalignment, excessive heat, or overloading to help resolve any issues or problems with the gear’s performance. Inside the machine shop, we build up and regrind Gears to critical tolerances, repair journals and bearing surfaces, and build replacement components. We can plate Gears to improve performance as well as apply a heat treatment. With our equipment assets and specialized experience, no repair is too difficult or too complicated.

We have 30-ton lifting capacity and handle all types of Gearboxes of any size. Working two shifts per day allows us to provide a fast turnaround, and rush and emergency services are available. Examples of gear types we recondition and repair include Helical, Double Helical, Herringbone, Bevel, Worm, and many others. To learn more about our reconditioning and repair services or any of our other capabilities, including rollers, pumps, and blowers repair and to recondition, contact us directly.